How PBT Bandage Design Enhancements Improve Controlled Pressure and Trauma Care Outcomes

When it comes to emergency wound care, delivering consistent and controlled pressure can mean the difference between stabilizing a patient or escalating blood loss. The Pressure Bandage Technique (PBT) has evolved as a response to this challenge, offering a practical, effective method for hemorrhage control in both pre-hospital and clinical environments. While the concept of pressure application is not new in wound care, the engineering behind modern PBT bandages has transformed how pressure is distributed, maintained, and adjusted during emergency response situations.

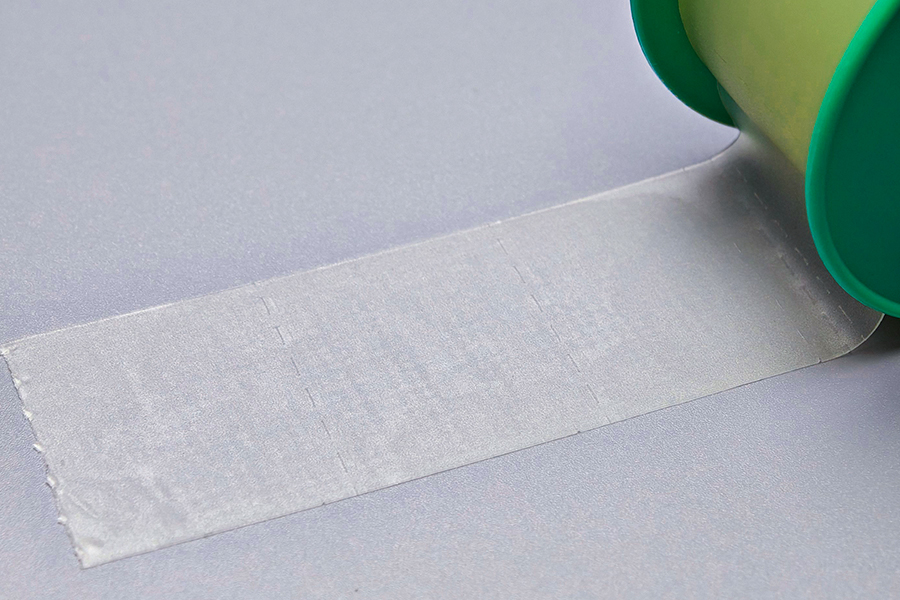

At the core of this innovation is the multi-layered design that allows PBT bandages to simultaneously absorb exudate and apply firm, localized pressure. Unlike basic elastic wraps, PBT solutions incorporate structured wound pads positioned to target the bleeding site directly. These pads are designed not just for absorption but for pressure transfer, creating a focused compression area without compromising circulation in surrounding tissue. This structural design is critical for managing deep lacerations or puncture wounds, where standard dressings may not offer sufficient force to stop hemorrhaging quickly.

The outer layer of the pressure bandage is just as crucial. Depending on whether elastic or non-elastic materials are used, manufacturers can control the amount of stretch and resistance the bandage offers when wrapped. High-quality PBT bandages often use carefully calibrated elasticity that allows for consistent compression even during movement, which is essential during patient transport. The material science behind this layer involves a balance of durability, stretch recovery, and breathability—ensuring the dressing performs in both fast-paced trauma situations and longer-term field applications.

Advanced versions of the Pressure Bandage Technique also feature built-in tension indicators or securing mechanisms such as hook-and-loop closures. These features are not just convenient—they enhance clinical accuracy. Tension indicators help medical personnel apply the right amount of force, reducing the risk of under- or over-compression. Secure fastenings prevent loosening, which can compromise pressure and effectiveness. For professionals working under pressure, especially in military or disaster zones, these design details offer both speed and reliability when every second counts.

It’s important to note that the mechanical pressure applied by PBT bandages is not merely about stemming bleeding—it also contributes to reducing swelling and improving stabilization, especially in limb injuries. This is why their use is expanding beyond trauma kits to include orthopedic and post-surgical applications. In many scenarios, PBT-style bandages can offer an efficient interim solution before advanced surgical care is available, which adds to their value in emergency preparedness and mobile medical units.

As a manufacturer committed to improving trauma care outcomes, we’ve invested significant R&D resources into optimizing the architecture of PBT bandages. Our focus has been on pressure uniformity, application speed, and user feedback integration. From material selection to quality assurance testing, every layer and closure is designed with real-world field use in mind. The evolution of this product line reflects ongoing collaboration with EMS providers, combat medics, and healthcare professionals in high-stakes settings.

The demand for reliable bleeding control products continues to rise as institutions seek solutions that combine ease of use with proven clinical performance. Our PBT bandage range meets this demand head-on, aligning modern engineering with life-saving functionality. Whether for trauma kits, ambulance inventory, or field deployment, these pressure dressings represent a dependable tool for fast-acting care when it matters most. And as export partners look for scalable, quality-assured products, our production capabilities are built to deliver consistent supply and customization options.

Ultimately, what sets the Pressure Bandage Technique apart is not just its ability to compress a wound—it’s the result of engineering precision, medical feedback, and design foresight. These aren’t just bandages; they’re the product of real-world challenges translated into practical solutions. For buyers seeking a balance of performance and reliability, a well-made PBT bandage delivers the confidence that critical care begins the moment the dressing is applied.

English

English Français

Français Español

Español Português

Português عربى

عربى