Spill Kits for Hospitals — Design, Function & Management

Spill management in healthcare requires purpose-built kits that remove hazards quickly, protect staff and patients, and ensure regulatory compliance. This article explains what spill kits are designed for, how spill kits in hospitals differ from industrial sets, and the specific functions of spill containment kits — with practical steps, component lists, and a comparison table to guide purchasing and training decisions.

What spill kits are designed for (core objectives)

A spill kit is engineered to enable a rapid, controlled response to liquid releases. Every kit's design focuses on: preventing spread of contamination, protecting staff and patients, enabling safe collection and disposal, and preserving evidence when required (for medication or hazardous incidents). In hospitals, kits are optimized for biological fluids, pharmaceuticals, cleaning chemicals, or mixed-chemical events.

Primary practical functions

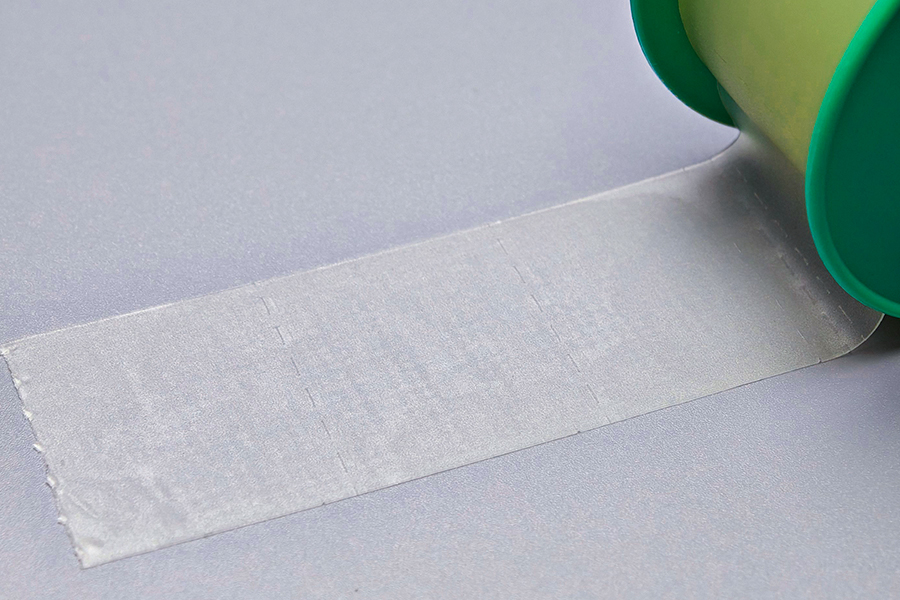

- Containment — stop liquid spreading using absorbent booms, socks, or instant dams.

- Absorption and neutralization — absorbents and neutralizers tailored to blood, cytotoxic drugs, acids or alkalis.

- Protection — PPE (gloves, gowns, masks, face shields) to prevent exposure while cleaning.

- Safe collection & disposal — containment bags, sharps containers, and labeled waste sacks for appropriate disposal routes.

- Documentation — incident forms, chain-of-custody or logs for regulated substances or sentinel events.

Spill kit in hospital — types, components and placement

Hospitals commonly use several kit types because risks vary by area. A correct selection and strategic placement reduces response time and cross-contamination. Below are common types and the highly recommended components for each.

Common hospital kit types and typical components

- Blood & body fluid kit — absorbent granules or pads, biohazard disposal bags, forceps/spatulas, PPE (gloves, eye protection), disinfectant wipes, instruction card.

- Cytotoxic/pharmaceutical spill kit — specialized absorbents that do not generate dust, disposable gowns, double-layered waste bags, labeled containment, and neutralizers where applicable.

- Chemical spill kit (small-volume) — universal absorbent pads, chemical-resistant gloves, goggles, sorbent socks, neutralizing powders (acid/alkali), and SDS quick-reference.

- Large-area containment kit — absorbent booms, instant berms, squeegees, wet/dry vac adapter components (if used by trained personnel).

| Kit Type | Typical Contents | Primary Use | Disposal |

| Blood & body fluid | Pads, scoop, biohazard bags, PPE, disinfectant | Patient-room spills, labs | Clinical waste stream |

| Cytotoxic/pharma | Non-dusting absorbents, gowns, double bags | Spills of chemo or hazardous meds | Hazardous waste protocols |

| Chemical (small) | Neutralizers, gloves, goggles, sorbents | Cleaning-agent or disinfectant spills | Follow SDS & hazardous waste rules |

Spill containment kit function — step-by-step on-scene workflow

The containment kit's purpose is to isolate the hazard immediately and make the area safe for removal. The steps below are a practical checklist that can be printed and placed in every kit.

Immediate response checklist (use in this order)

- Assess risk — identify liquid type from labels, odor, or patient context; do not touch without PPE.

- Isolate area — cordon off with signage or barriers to prevent foot traffic and secondary contamination.

- Contain the spread — apply absorbent socks/booms around perimeter; place instant berms if floor drains are nearby.

- Control vapors if applicable — ventilate the area if chemical vapor is suspected and safe to do so per SDS and local policy.

- Absorb and collect — use pads and scoops, then transfer waste into the correct labeled bag/container.

- Disinfect and document — apply appropriate disinfectant contact time for biological spills; complete incident reports and waste manifesting steps.

Selecting, stocking and maintaining spill kits

Selection should be risk-based: map high-risk areas (pharmacy, oncology, labs, isolation rooms) and supply kits sized to likely spill volumes. Maintain a visible inventory card in each kit and a central log showing last restock date and responsible staff. Regular audits and replacement of single-use items are essential to ensure readiness.

Practical maintenance checklist

- Monthly kit inspection for expired or used items.

- Replace absorbents after any event and log the incident.

- Verify PPE sizes and that disposal bags/containers meet current waste handling rules.

- Update SDS/reference cards if products in use change.

Training, drills and documented procedures

Spill management is only effective when staff are trained and confident. Training should be role-specific (clinical staff, environmental services, pharmacy) and include hands-on practice with the exact kits stocked on site. Drills should measure time-to-containment, correct PPE use, and proper waste segregation.

Key training elements to include

- Recognizing spill types and reading SDS or medication labels.

- Hands-on practice with containment, absorbents, and safe transfer to waste containers.

- Documentation and incident escalation criteria (when to call EHS or a hazardous-materials team).

- Post-incident debrief and root-cause review for process improvement.

Well-designed spill kits, clearly defined containment functions, and regular training together form the backbone of effective spill management in hospitals. Implement risk-based placement, maintain ready-to-use kits, and reinforce clear, practiced procedures so that spills are contained quickly and safely with minimal disruption to patient care.

English

English Français

Français Español

Español Português

Português عربى

عربى