Cost-Effectiveness and Total Cost of Ownership

How does your dressing contribute to reducing the Total Cost of Wound Care (TCO)?

Our bandages reduce TCO through: (1) extended wear time reducing change frequency by up to 40%, (2) improved patient compliance minimizing complications, and (3) lower material waste. Elastic bandages manage edema and venous issues, preventing costly complications like ulcer formation and infection.

Can you provide case studies or data demonstrating ROI?

Typical ROI improvements include: reduced dressing change frequency (PBT bandages last 5-7 days vs. 2-3 days for standard products), improved compliance with self-adherent Cohesive Bandages, and reduced material waste. Institutions typically report 15-25% ROI improvement within the first year. We can provide pilot program analysis templates tailored to your facility.

What is the recommended wear time?

Fixation bandages: 5-7 days depending on primary dressing change cycle. Elastic compression bandages: 8-12 hours daily (worn during day, removed at night). POP bandages: 4-8 weeks for continuous fracture immobilization. All recommendations follow established clinical guidelines and should be individualized based on patient assessment.

Clinical Efficacy and Value-Based Procurement

What clinical evidence supports your products' superior performance?

Our products comply with EN 14079 (European gauze standard) and international compression therapy guidelines (American Venous Forum, European Wound Management Association). All products undergo rigorous testing for tensile strength, elasticity, breathability, and biocompatibility. We maintain partnerships with leading research institutions and contribute to peer-reviewed literature.

How does your product manage highly exuding wounds and prevent maceration?

Our bandages function as secondary dressings. Gauze and Crepe bandages offer excellent breathability facilitating moisture evaporation. They secure primary absorbent dressings (alginate, foam) in place, preventing migration and ensuring effective exudate management. This layered approach prevents maceration while managing high-volume exudate.

Is the dressing suitable for sensitive skin or high-risk populations?

Yes. Our PBT and Gauze bandages use hypoallergenic materials. Cohesive Bandages are latex-free, non-adhesive, and leave zero residue—ideal for pediatric, elderly, and fragile skin patients. Non-adhesive removal prevents skin tears and trauma, making them suitable for frequent dressing changes and patients with epidermolysis bullosa or similar conditions.

Do you offer antimicrobial options?

Our basic bandage series are mechanical support devices without antimicrobial agents. We offer specialized antimicrobial gauze bandages featuring silver technology. Silver ions disrupt bacterial cell walls, inhibit DNA replication, and prevent biofilm formation. Effective against MRSA, Pseudomonas, fungi, and some viruses with sustained release throughout wear period.

Product Quality, Specifications, and Compliance

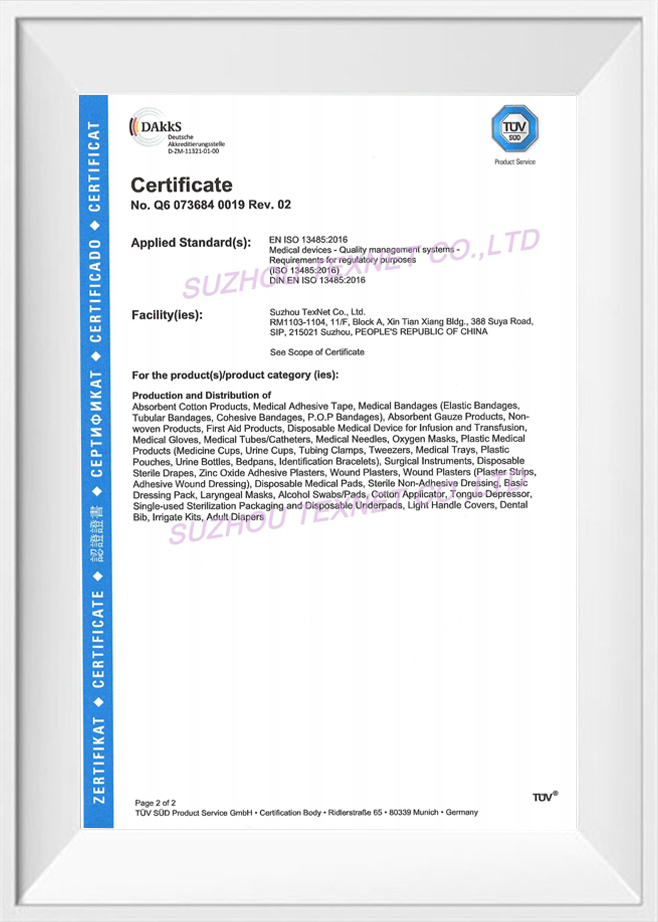

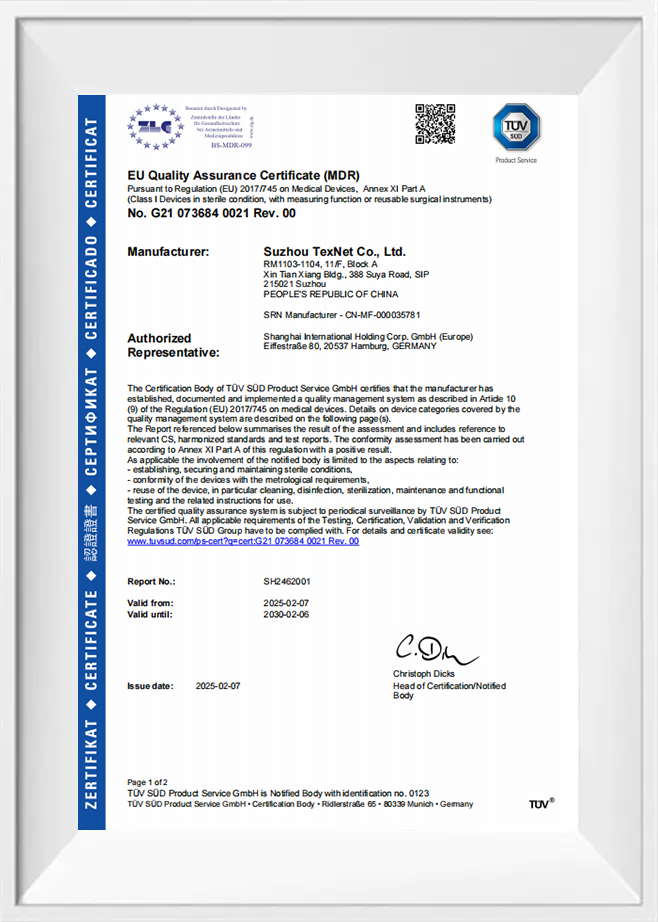

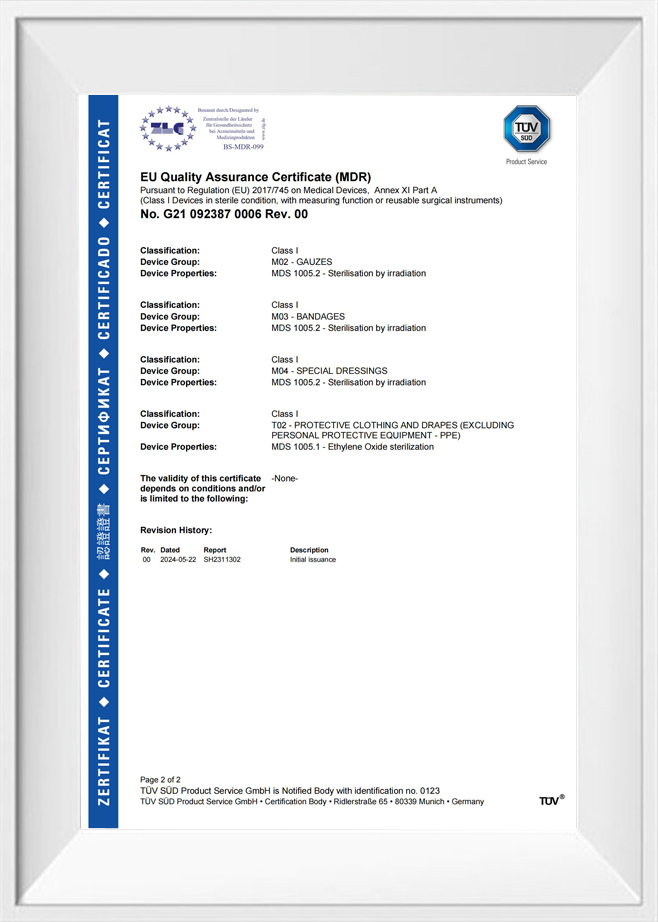

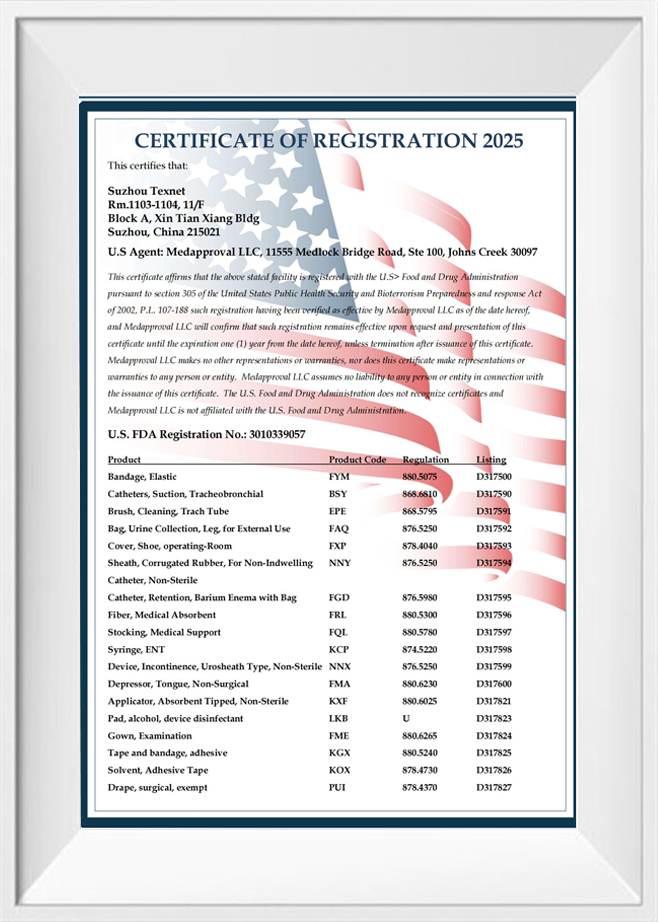

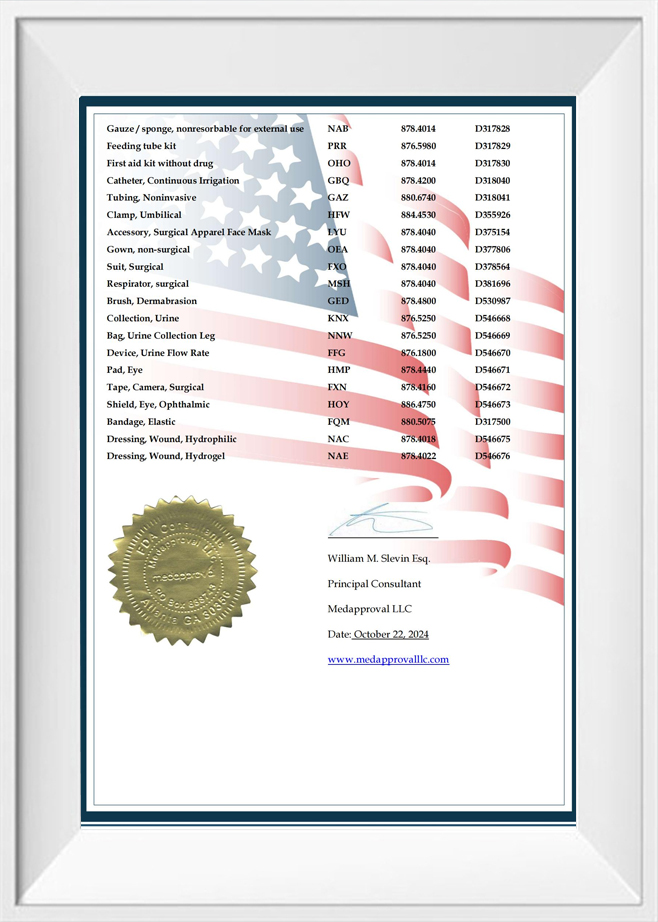

What international regulatory approvals does your product line hold?

All products hold European CE Mark (MDR 2017/745 compliant). Manufacturing facilities are ISO 13485:2016 certified. Select products (POP, advanced formulations) have FDA 510(k) clearance. Additional compliance: EN 14079 (gauze dressings), ISO 9001:2015, ISO 14644 (cleanroom standards). Complete regulatory documentation available upon request.

What is your quality control process?

Multi-layered QC: (1) Raw material inspection for purity and specifications, (2) In-process control monitoring density, tension, and dimensions in real-time, (3) Finished product testing for elasticity, tensile strength, sterility, and packaging integrity, (4) Statistical process control with control charts and capability analysis, (5) Complete batch traceability and 10-year record retention.

Supply Chain, Logistics, and Support

How do you ensure stable global supply chain for bulk orders?

We maintain: (1) Long-term supplier contracts with geographic diversity, (2) Multiple automated production facilities with excess capacity, (3) 30-45 days safety stock across distributed warehouses, (4) Global logistics partnerships with real-time tracking, (5) Business continuity and contingency plans for disruptions. Dedicated account management for large-volume customers ensures reliable fulfillment.

English

English Français

Français Español

Español Português

Português عربى

عربى