Medical Tape Guide by TEXNET: Microporous, Paper, Silk & More

Why Medical Tape Matters More Than It Looks

Medical tape is a quiet workhorse in clinical care: it secures dressings, stabilizes devices, and helps protect fragile skin by keeping fixation reliable without frequent rework. In practice, “good adhesion” is only one part of the equation—breathability, skin comfort, edge integrity, and visibility can be just as decisive for day-to-day outcomes.

TEXNET has focused on medical-grade fixation materials since 2002, supporting healthcare and distribution partners with a portfolio that spans mainstream and specialty medical tape needs, while building the manufacturing and compliance foundation required for consistent, repeatable supply.

What Defines a High-Performance Medical Tape

Selecting medical tape is essentially balancing performance trade-offs. The most effective specifications translate clinical intent (secure, gentle, breathable, observable) into measurable product behaviors.

- Breathability and moisture management to reduce heat and humidity buildup under fixation.

- Skin-friendly adhesion designed to hold securely while minimizing discomfort during removal, especially on sensitive or frequently re-taped areas.

- Process consistency (straight edges, stable unwind, predictable tack) that improves application speed and reduces lifting or rework.

- Use-case fit: visibility for monitoring, rigidity for immobilization, or fabric feel for comfort—depending on where and how it is used.

In procurement terms, the “best” medical tape is the one that meets your clinical and commercial requirements with the lowest variability—because variability is what drives complaints, returns, and avoidable handling time.

Common Medical Tape Types and How They Differ

Below are five widely used categories—each with a distinct material logic and value proposition. When the product story is anchored in the right use-case, it becomes both more scientific and more persuasive.

| Tape category | Typical application | Material/experience | TEXNET-style value anchor |

|---|---|---|---|

| Microporous tape | Breathable fixation for dressings | Non-woven backing with thousands of micro-pores | Controlled airflow and moisture vapor management to help reduce maceration risk |

| Zinc oxide plaster | Classic rigid fixation and support | 100% cotton base with zinc oxide adhesive system | A heritage “skin-tolerant” positioning with strong, stable hold |

| Medical paper tape | Everyday, gentle fixation | Paper-like backing designed for easy handling | Precision-cut edges for straighter laydown and reduced edge lift perception |

| Transparent/clear medical tape | Fixation where visual checks matter | Clear film for visibility | “Observe without removal” positioning for wound/exudate/skin status monitoring |

| Silk medical tape | Comfort-focused fixation | Silk-like fabric backing with smooth touch | Lower-friction feel for a premium comfort narrative without sacrificing usability |

Microporous tape: engineered breathability

In microporous tape, the story is not simply “breathable,” but breathability that is engineered—micro-porous structures in the backing support sustained ventilation and moisture vapor flow. This is especially relevant where occlusion can lead to uncomfortable heat and humidity buildup beneath the tape.

Zinc oxide plaster: classic cotton-based fixation

Zinc oxide plaster remains a dependable category for customers who value a familiar, rigid fixation profile. A cotton base paired with a zinc oxide adhesive system supports a traditional positioning: stable hold with a “time-tested” skin tolerance narrative, often favored in support and immobilization contexts.

Medical paper tape: consistency that improves application

For medical paper tape, subtle manufacturing details can materially change user experience. Straight, consistent edges help tapes lay down smoothly and look professional on the skin, which matters in both clinical presentation and consumer retail expectations.

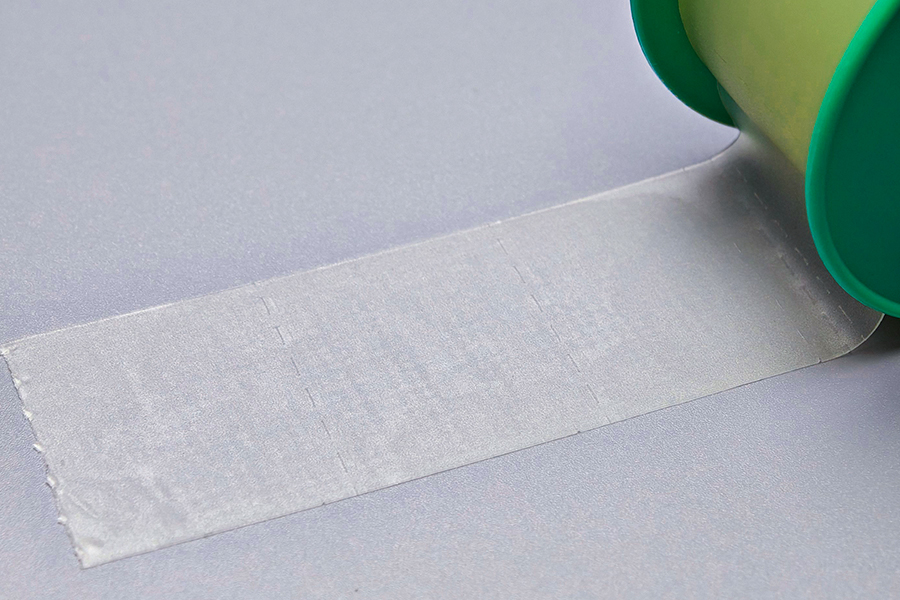

Transparent/clear medical tape: visibility as a functional benefit

Transparent/clear medical tape earns its place when observation is part of the workflow. A clear film can support visual checks of the underlying area without disturbing fixation—turning “transparency” from a cosmetic feature into a practical advantage.

Silk medical tape: premium comfort positioning

Silk medical tape is often chosen for its tactile experience. A silk-like fabric backing provides a smoother, lighter feel and can reduce the “drag” sensation during movement, which supports a comfort-forward product story for sensitive skin or frequent-use scenarios.

Compliance and Supply Readiness: The Manufacturer Behind the Tape

Medical tape sits at the intersection of materials science and regulatory discipline. For brands and distributors, manufacturer selection is as much about quality systems and delivery capability as it is about the tape itself.

- Quality management alignment: TEXNET operates under TÜV-issued CE and ISO 13485 credentials, supporting consistent documentation and controlled production.

- Market access preparedness: TEXNET is registered with the U.S. FDA, helping partners streamline supplier qualification for U.S.-bound programs (registration status does not imply clearance for every product).

- Materials and labeling needs: options such as latex-free positioning can be integrated into product planning where relevant.

- Commercial scalability: B2B delivery support including OEM/ODM, private label programs, and packaging/export fulfillment.

- Sterilization planning: customizable sterilization specifications can be developed for programs that require it.

The practical takeaway is simple: when your medical tape supplier can control variability and documentation, your downstream brand risk decreases—while your speed to market improves.

How to Specify Medical Tape for OEM/ODM and Private Label

If you are developing a private label portfolio, align your medical tape specification with the use-case first, then build the commercial and regulatory layers around it. A disciplined brief also helps suppliers propose the right construction instead of defaulting to a “closest match.”

- Define the scenario: dressing fixation, device securing, rigid support, or visibility-first monitoring.

- Select the category: microporous tape, zinc oxide plaster, medical paper tape, transparent/clear medical tape, or silk medical tape.

- Confirm the user experience: unwind feel, edge straightness, comfort expectations, and removal preference.

- Finalize commercialization: labeling language (e.g., latex-free where applicable), packaging format, and export delivery requirements.

- Lock compliance and documentation: ensure the supplier’s quality system, change control, and traceability fit your market needs.

By structuring selection this way, your product education (the “why” behind each tape type) naturally supports marketing claims—because the claims are grounded in construction logic, not slogans.

Note: always follow local regulations and clinical protocols for intended use, claims, and labeling of medical tape products.

English

English Français

Français Español

Español Português

Português عربى

عربى