Animal Health Care Supply List: Dressings, Bandages, Swabs & Gloves

In veterinary clinics, shelters, and on-farm treatment areas, wound care success depends on consistency: the right consumables, always in stock, always performing the same way. As a manufacturer and supplier of medical disposables used in animal health settings, I’ve seen how a well-built supply list reduces treatment delays, standardizes outcomes across teams, and keeps costs predictable.

How I build a reliable animal health care supply list

When customers ask us for an animal health care supply list, I start with two questions: what species you treat most, and where the care happens (clinic room, mobile service, barn). Then we standardize the core items so every wound kit looks the same—whether it’s a small animal exam room or a large animal field call.

A practical baseline is to plan consumption per case. For routine wound cleaning + dressing, many teams typically use 6–12 swabs (for cleaning and drying), 1–2 dressing layers (contact + absorbent), and 2–3 pairs of gloves (prep, procedure, cleanup). Those numbers help you forecast weekly usage and set a reorder point instead of guessing.

A simple stocking math example you can apply

If a clinic handles 15 wound/skin cases per week and averages 8 swabs per case, that’s 120 swabs/week. Add 20% for waste, re-cleans, and training, and you should stock about 144 swabs/week. With a target of 4 weeks on hand, your minimum on-shelf level becomes roughly 576 swabs—before you even think about seasonality.

From there, we map each item to a clear purpose: contact layer, absorption, fixation/compression, and barrier protection. The table below is the same framework we use with distributors and clinics to keep procurement simple and auditable.

| Category | What to Specify in Your PO | Typical Use in Animal Care | Stocking Tip |

|---|---|---|---|

| Dressings | Sterile/non-sterile, absorbency level, adhesion type, size range | Covering, absorbing exudate, protecting fragile tissue | Keep 2–3 common sizes; standardize packaging for faster picking |

| Bandages | Stretch %, length/width, cohesive vs elastic, edge finish | Fixation, compression, limb support, securing dressings | Set a “per kit” count and reorder by kits, not single rolls |

| Swabs | Woven vs non-woven, ply, sterility, lint level, sizes | Cleaning, drying, applying antiseptics, prepping sites | Track weekly burn rate; swabs are the #1 silent stockout |

| Gloves | Material, size range, powder-free, texture, cuff length | Barrier protection, cross-contamination control, hygiene | Use a two-bin system to avoid “empty box” surprises |

Dressings: match the wound needs, not a generic “one pad fits all”

In animal health, dressing performance is tested by hair, movement, moisture, and unpredictable environments. The dressing set that works on a calm indoor patient may fail quickly on a working dog or a large animal in a barn. I recommend building your dressing list by layers:

Contact layer (protect tissue, reduce sticking)

A non-adherent contact layer can help reduce trauma during dressing changes, especially when exudate or delicate tissue is present. For customers who want a consistent, low-stick option across departments, we usually suggest standardizing a couple of sizes from our non-adherent pads page.

Absorbent layer (manage exudate and cushion movement)

Non-woven wound dressings are popular when teams want soft handling, reliable absorbency, and low lint. They’re also easy to standardize across clinics because the feel and performance remain consistent between batches. If you’re comparing options, you can reference our non-woven wound dressings page as a starting point for spec discussions.

Protective/film layer (seal and protect when appropriate)

For scenarios where a protective film helps shield from friction or external moisture, PU film-style dressings are commonly considered. The key procurement detail is clarity on adhesion strength and wear time expectations—because animal movement can stress edges. For buyers building a full dressing matrix, our PU wound dressings page is useful for aligning your team on format and packaging preferences.

If you want to simplify purchasing, we often consolidate dressing choices into 2–3 standard size groups (small, medium, large) and then select the right combination of contact + absorbent + fixation for each protocol. This keeps training simple and reduces “wrong item” usage.

For teams that prefer to source a broader dressing range under one category, you can also browse our procedure kits & dressings page to see the formats we support for consolidated purchasing.

Bandages: fixation and compression that stays put without risking circulation

Bandaging in animal health is a balancing act: it must hold through movement, but it can’t be so tight that it compromises circulation—especially on distal limbs. When we supply bandage programs, we typically separate bandages into three practical roles: wrap/secure, stretch/compress, and cohesive “self-grip” fixation.

Gauze rolls and gauze bandage wraps for foundational layering

Gauze rolls are a dependable base layer for many clinics because they’re breathable and easy to tear and shape. For standardized procurement, buyers often specify width/length ranges and packaging format so staff can pick quickly. If you want a direct reference point, start with our gauze rolls and bandages page.

Elastic bandages for controlled stretch and support

Elastic bandages are commonly used when you need controlled stretch for fixation or mild compression. The purchasing detail that matters is consistency: the same stretch behavior roll-to-roll makes application training easier and reduces rework. If your team uses elastic bandages frequently, our elastic bandages page is a helpful internal reference for standardizing sizes and formats.

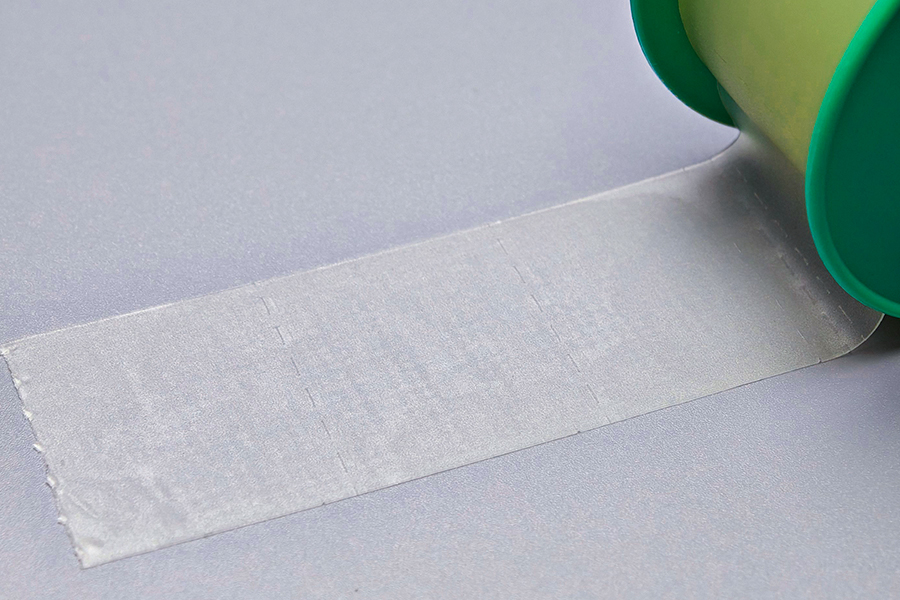

Cohesive bandages for fast fixation (especially in active patients)

Cohesive wraps are often chosen when teams want quick fixation that grips to itself without sticking aggressively to hair. For procurement, define whether you need a lighter cohesive wrap for simple fixation or a stronger cohesive for more demanding movement. Many buyers review our cohesive bandages page when setting a consistent clinic-wide wrap standard.

Procurement tip: instead of ordering “a mix of rolls,” define bandage sets per treatment kit (for example: 1 gauze roll + 1 absorbent dressing + 1 elastic wrap + 1 cohesive wrap). Your inventory then becomes “kits on hand,” which is far easier to manage than tracking single items.

Swabs: the quiet workhorse for cleaning, drying, and prepping

Swabs disappear quickly because they get used everywhere: wound cleaning, drying before dressing application, applying antiseptics, and general hygiene tasks. If your team is ever “out of swabs,” efficiency drops immediately—so I treat swabs as a first-priority stocking item.

Woven cotton gauze swabs for versatile absorption

Gauze swabs are widely used because they’re absorbent and familiar. Many veterinary customers standardize common footprints (like 2"x2", 3"x3", 4"x4", and 4"x8") so staff can pick the right size by sight. For internal reference when you’re aligning purchasing specs, see our gauze swabs page.

Non-woven swabs for low-lint performance and consistent handling

Non-woven swabs are often preferred when teams want soft contact, low lint, and consistent performance—especially in protocols where reducing fiber shedding matters. If you want to compare formats or discuss sterility options, our non-woven swabs page is a clear place to start.

Alcohol pads for quick site prep and hygiene steps

For quick disinfection steps, alcohol pads are a simple way to keep workflows consistent across teams and locations. Buyers typically define size and packaging based on whether the pads are used at the exam table, in mobile kits, or in larger prep areas. You can reference our alcohol pads page when standardizing your clinic’s preferred format.

- Standardize 2–3 swab sizes so staff don’t “overuse the big ones.”

- Set a weekly burn-rate target and keep 3–4 weeks on hand for swabs in high-volume settings.

- Choose sterile vs non-sterile based on your internal protocol and procedure category.

Gloves: barrier protection and cross-contamination control

Gloves aren’t just PPE—they’re part of your infection-control workflow and your team’s confidence. In animal health environments, gloves also deal with disinfectants, friction, and frequent donning/doffing. That’s why we encourage buyers to specify glove performance requirements instead of purchasing “whatever is cheapest.”

What to define when purchasing gloves

- Material choice (for example, latex vs other materials), aligned with your staff sensitivity considerations and usage environment.

- Powder-free requirement for cleaner handling and reduced residue concerns.

- Grip/texture needs for wet handling (cleaning, prepping, dressing application).

- Size range strategy: ensure you stock enough of the most-used sizes to prevent unsafe “wrong size” substitutions.

If you’re aligning your glove program across multiple clinics, start with our medical gloves page to define baseline requirements (sizes, weights, packaging format). Then we can help you translate those into a consistent purchase spec for stable supply.

Operational rule that reduces waste: treat gloves like swabs—high burn rate, high risk of sudden stockout. Two-bin storage (one active, one reserve) prevents last-minute substitutions and urgent reorders.

A buyer’s checklist I use to prevent supply problems

Whether you’re a clinic group buyer or a distributor building an animal-health line, the fastest way to reduce issues is to purchase by specification and performance, not by product name alone. Here’s the checklist we use in onboarding calls to align requirements before quoting.

- Define your top 5 use-cases (routine wound care, post-op dressing, field treatment, grooming-related abrasions, infection-control).

- Standardize sizes (limit variation to what staff can reliably pick without checking labels).

- Choose sterility level per protocol, and keep it consistent to avoid mis-picks.

- Set reorder points using real usage data (weekly burn rate × lead time) plus a safety buffer.

- Document acceptance checks on arrival (packaging integrity, labeling, batch traceability, and basic performance verification).

How we support distributors and clinics as a manufacturer and supplier

Our job isn’t to push products—it’s to help you build a stable, repeatable supply program that your staff trusts and your customers can rely on. That means consistent materials, predictable packaging, and professional documentation for your market requirements.

What you can expect from our supply approach

- Specification-driven quoting: you define performance and packaging needs, and we match products accordingly.

- Batch consistency: swabs, dressings, and bandages should feel and perform the same across deliveries.

- Private label/OEM readiness where applicable, with clear artwork and labeling alignment for your channel.

- Consolidated shipments across categories so you can reduce vendor count and simplify inbound receiving.

If you’re building or expanding your animal health care supply list and want to keep everything under one supplier, start from our products page and tell us your use-cases, target market, and expected monthly volume. We’ll help you narrow the list to a practical SKU set that’s easy to order, store, and train on.

Bottom line: the best supply list is the one your team can execute without hesitation—right item, right time, consistent performance.

English

English Français

Français Español

Español Português

Português عربى

عربى