Worksite First Aid Station Supply Setup | Manufacturer Guide

Define What Your Worksite First Aid Station Must Handle

When customers ask me for a worksite first aid station supply setup, I start with one practical question: “What injuries are you most likely to treat before professional care arrives?” The best station is not the biggest—it is the one that matches your hazards, workforce size, and access time to outside medical services.

A quick risk-and-usage checklist I use with buyers

- Work type: office/light industrial vs. maintenance vs. construction vs. hot work (welding/cutting) vs. chemical handling

- Workforce: peak headcount per shift, contractors included (not just payroll employees)

- Worksite layout: single zone vs. multiple buildings/floors; walking time from the farthest point

- Top incident patterns: minor cuts/abrasions, burns, eye irritation, sprains, deeper lacerations, crush risk

- Environmental stress: dust, heat, moisture, cold storage, UV exposure (these directly affect packaging and shelf life)

If your hazards can produce severe bleeding or serious burns, I typically recommend planning beyond a “basic kit” mindset. In ANSI terms, many customers use Class A as a baseline for common injuries and step up toward Class B when there is higher risk of serious injuries; the final decision should come from your site assessment and safety program. Documenting that decision makes restocking and audits much easier.

Station Placement and Cabinet Layout That Reduce Response Time

A worksite first aid station is only effective if people can reach it quickly and find supplies without searching. In practice, I see two common failures: a single cabinet that is too far away, and a cabinet that is overfilled but disorganized.

Placement rules that work across most sites

- Duplicate coverage across zones: if you have separate buildings, floors, or work areas, treat each as its own “mini site.”

- Choose “clean access” points: near break areas, supervisor stations, or tool cribs—away from locked rooms and away from heavy traffic that blocks access.

- Mount at a consistent height and keep it visible: signage matters more than most buyers expect during a stressful incident.

- Add a portable “grab kit” where work moves (maintenance routes, construction crews, field technicians).

How I organize the cabinet to prevent “panic searching”

- Top shelf: PPE and quick barriers (gloves, eye protection, wipes).

- Middle shelf: bleeding control and dressings (gauze, pads, bandages, tape).

- Lower shelf: bulk refills and less-used items (cold packs, triangular bandages, burn dressings).

- Door panel or labeled pouch: scissors/tweezers and “instructions + emergency contacts.”

The objective is simple: a trained worker should be able to open the station and locate the correct supply category in under 10 seconds. That target usually requires labels, a consistent layout across all stations, and a controlled refill process.

Core Supplies for a Worksite First Aid Station

Below is the supply structure I recommend most often. It is designed for quick treatment of common worksite injuries—then scaled up based on headcount, risk level, and incident history. Where it helps, I include internal references so you can review specifications on our site without forcing a purchase decision.

Wound cleaning and skin prep

- Antiseptic/alcohol prep: useful for quick cleaning before dressing; see our alcohol pads page.

- Cleaning wipes for hands/surfaces: keep treatment cleaner and reduce cross-contamination risks.

Bleeding control and dressings

- Sterile gauze (pads, rolls, swabs): the highest-consumption refill item on most worksites; review options on our gauze products page.

- Bandages for coverage and support: for cuts, abrasions, and wrap support; see our bandage manufacturers page.

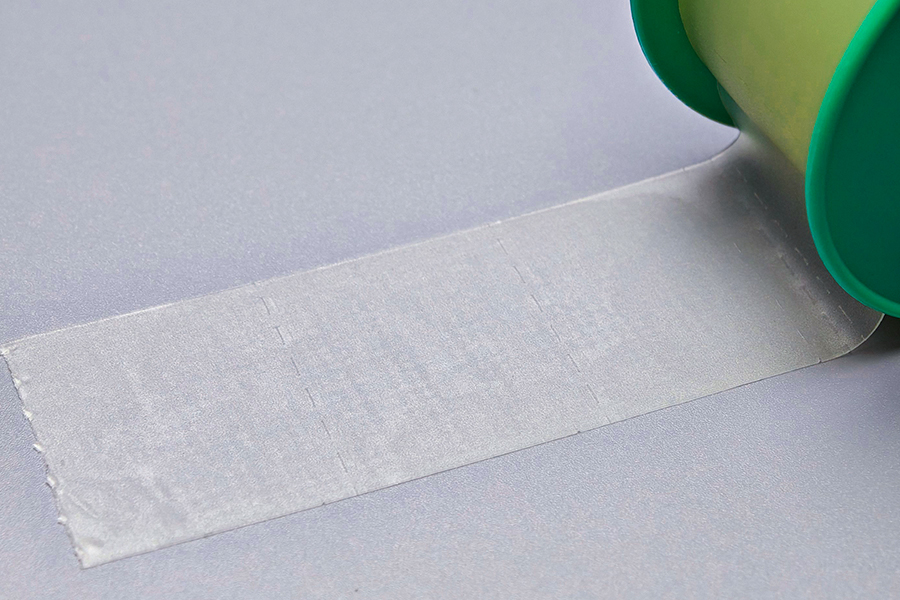

- Medical tapes: choose based on skin sensitivity, moisture, and adhesion needs; see our medical tapes page.

- Specialty dressings: finger dressings, non-adherent pads, wound plasters—useful in high-hand-injury environments.

Burn and eye care (add based on hazard)

- Burn dressings: particularly relevant for hot work, kitchens, and any environment with heat sources; see our burn dressings page.

- Eye pads and related coverings: useful for dust/particle irritation or minor trauma; see our eye pads page.

- Eye/face protection for responders: if you anticipate contact with blood or body fluids, plan PPE consistent with your exposure-control approach; see our protective glasses page.

Tools and “make it usable” items

- Trauma shears/scissors and tweezers: for cutting tape, clothing, or bandage wraps.

- Disposable gloves in multiple sizes: align with your hygiene and exposure-control practices.

- Simple job aids: quick reference card, emergency contacts, and a restock checklist attached to the inside door.

If you prefer to standardize your station with a pre-configured kit plus refills, you can review options on our First Aid Kits page. We often customize kit contents to match worksite hazards and purchasing standards.

Sample Quantity Planning (Practical Starting Point)

Buyers frequently ask me for “the right number” of each item. There is no single universal number, but you can set a defensible baseline by combining (a) headcount, (b) hazard severity, and (c) expected consumption of high-use items (bandages, gauze, wipes, tape).

| Supply group | Lower-risk site (office/light industrial) | Higher-risk site (maintenance/construction) | Why it matters |

|---|---|---|---|

| Adhesive bandages / small dressings | 50–80 pcs | 120–200 pcs | Typically the highest-consumption item for minor cuts/abrasions |

| Sterile gauze pads (assorted) | 30–50 pcs | 60–120 pcs | Controls bleeding and creates a clean base under wraps |

| Gauze rolls / wrap gauze | 6–10 rolls | 12–24 rolls | Secures pads and supports bleeding control in larger wounds |

| Elastic/cohesive bandage wrap | 4–8 rolls | 10–16 rolls | Useful for compression, sprains, and securing dressings in active work |

| Medical tape (assorted) | 6–10 rolls | 10–20 rolls | Tape selection affects dressing security under sweat, dust, and movement |

| Alcohol pads / antiseptic wipes | 50–80 pads | 100–160 pads | Supports basic cleaning prior to covering wounds |

| Burn dressings (if heat risk) | 0–4 pcs | 6–12 pcs | Scale based on hot work frequency; keep separate from general wound stock |

| Eye pads (if particles/dust risk) | 2–6 pcs | 6–12 pcs | Useful for minor trauma support; separate from eyewash requirements |

| Gloves (pairs) | 25–50 pairs | 50–100 pairs | Plan for multiple responders and repeated uses during clean-up/restock |

A simple scaling rule that prevents stockouts: for your top three consumables (usually bandages, gauze pads, and wipes), keep a two-week buffer on-site and set reorder points based on real usage, not assumptions.

Restock Control: The Difference Between “Installed” and “Operational”

Many worksites install a cabinet once and assume they are done. From a supplier perspective, that is where failures begin. Consumables expire, adhesive performance drops in heat/humidity, and high-use items disappear quietly until the day you need them.

A practical inspection rhythm

- After every use: replace what was used immediately (do not wait for the monthly audit).

- Weekly quick check: confirm seal integrity, cleanliness, and that top-use items are above minimum.

- Monthly full audit: count stock, record expirations, and log replenishment quantities.

- Quarterly shelf-life review: pull anything approaching expiration and rotate stock from central inventory.

How to make restocking fast and consistent

- Assign ownership: one role per shift or per zone (not “everyone”).

- Set min/max levels on the inside door (example: “Gauze pads 4x4: min 30, max 80”).

- Use consistent pack sizes for refills to avoid partial replenishment and counting errors.

- Store refills in a central “first aid bin” by category (gauze, bandage, tape, wipes) to reduce search time.

From a manufacturing standpoint, the most reliable approach is standardization: identical station layouts, identical refill SKUs, and a single checklist used across all locations. That is how you keep the system operational through staff turnover and changing work conditions.

Compliance Touchpoints You Should Build Into the Setup

Your first aid station should be aligned with your safety obligations and audit expectations. In the U.S., OSHA’s medical services and first aid standard expects adequate first aid supplies to be readily available, and it specifically calls out the need for quick drenching/flushing facilities where corrosive exposure is possible. These points strongly influence where you place stations and what hazard-specific supplies you add.

How I help customers create an “audit-ready” first aid station

- Match station contents to your written hazard assessment and incident history (use logs, near-miss data, and supervisor feedback).

- Choose a recognized baseline (many customers reference ANSI/ISEA Z308.1 Class A vs. Class B as a structured starting point) and then customize for site hazards.

- Add PPE that fits realistic exposure scenarios: gloves, eye protection, and barrier items for responders where needed.

- Keep documentation in the cabinet: last inspection date, restock record, and the current contents list.

One important nuance: standards can be used as guidance even when they are not adopted as law. Practically, that means you should be able to explain why your station is “adequate” for your specific worksite and show the inspection/restock evidence that keeps it that way.

Common Setup Errors I See (and How to Avoid Them)

Overfilling the cabinet instead of engineering usability

A cabinet that contains “everything” often contains nothing you can find quickly. Keep a disciplined core list, then store bulk refills separately and replenish using min/max levels.

Not stocking for the environment

Heat and humidity can reduce adhesive performance and shorten effective shelf life. Dust and sweat increase demand for wraps and tapes that hold under movement. If your site is harsh, prioritize sealed packaging and consistent monthly audits.

Treating “first aid station” as a single location

If your worksite has multiple zones, a single cabinet becomes a “best intention” instead of a real control. In those cases, the best improvement is often adding a second station plus a portable grab kit for moving work.

No ownership and no restock mechanism

If no one owns inspection and replenishment, the station will drift into non-compliance. Assign ownership, publish the checklist, and make replenishment easy with standard refill packs.

How TEXNET Support Worksite First Aid Station Supply Setup as a Manufacturer

As a manufacturer and supplier, my role is to make your first aid station reliable at scale: consistent materials, stable supply, and packaging that matches your working conditions. Many customers standardize on a core set of consumables (gauze, bandages, tapes, dressings, wipes) and then add hazard-specific items by site.

- Component-based setup: build fixed stations from verified refill categories and keep central backup inventory.

- Custom kitting: where it fits your process, we can help configure first aid kits with contents selected for your hazard profile.

- Procurement simplicity: align pack sizes and SKUs so your restock process becomes predictable and fast.

If you want to see our full range of components that can be used to build or refill worksite stations, you can start from our full products page and select the categories that match your setup plan.

English

English Français

Français Español

Español Português

Português عربى

عربى