How Non Woven Swabs Enhance Infection Control Across Medical and Cleanroom Environments

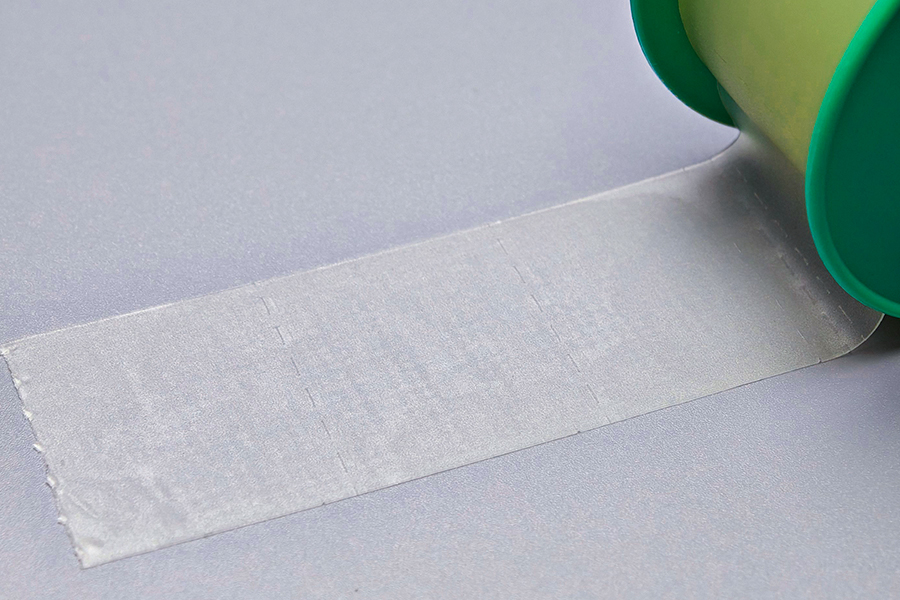

Infection control is one of the most critical priorities across modern healthcare and high-precision industries, and the tools used in daily protocols often determine the success of contamination prevention. Among these tools, Non Woven Swabs play an increasingly essential role due to their structural advantages and consistent performance. Their unique composition—formed by bonding fibers without weaving—results in a product that offers not just excellent absorbency but also minimal linting, a critical factor when maintaining sterility or reducing foreign particle introduction in sensitive environments.

Hospitals, laboratories, and cleanrooms rely on strict aseptic practices, and one of the key contributors to maintaining such environments is the use of disposable, sterile consumables. Non Woven Swabs meet these demands with precision. Their ability to deliver uniform fluid application and controlled specimen collection minimizes the risk of contamination from excess material or fiber shedding. Whether used to clean wounds, apply antiseptics, or handle microbiological samples, these swabs support predictable, repeatable procedures that align with infection control protocols required by institutions such as the CDC and WHO.

From a material science standpoint, Non Woven Swabs offer distinct benefits over traditional cotton variants. Because they are produced through thermal, chemical, or mechanical bonding rather than weaving, they allow for higher tensile strength and more controlled absorption. This manufacturing flexibility also supports a range of configurations, enabling swabs to be tailored for specific hospital departments, diagnostic labs, or pharmaceutical production lines. For instance, low-particulate swabs with cleanroom certification are widely adopted in pharmaceutical environments where even microscopic contaminants can compromise entire batches of product.

Sterility is another major factor where Non Woven Swabs truly shine. Many are available in sterile, individually packed formats to eliminate cross-contamination risks. This is especially valuable in operating rooms, emergency care settings, and microbiological testing, where patient safety and diagnostic accuracy cannot be compromised. As a manufacturer with deep experience in supplying to high-compliance sectors, we’ve observed growing demand for sterile-ready, shelf-stable formats that fit seamlessly into tightly controlled procedural workflows.

It's also worth noting that the versatility of Non Woven Swabs extends beyond healthcare. In electronics manufacturing and optical industries, their particle-free nature makes them ideal for cleaning precision instruments or removing residues without introducing new variables. Cleanroom environments benefit greatly from swabs that maintain integrity under pressure and don’t break down under exposure to solvents. This has positioned these swabs as the tool of choice for companies focused on reliability and high-performance standards.

When considering infection control, one cannot overlook the cost-effectiveness and operational efficiency that Non Woven Swabs bring to the table. Their single-use nature eliminates the need for sterilization between uses, saving both time and labor while reducing contamination risk. Combined with competitive pricing and scalable packaging solutions, these swabs are a smart, future-proof addition to any organization’s hygiene strategy. Our customers value this balance of performance and practicality—it's why our Non Woven Swabs continue to be trusted across diverse sectors.

In conclusion, Non Woven Swabs are not just a commodity—they are a critical component in the broader system of infection control and contamination prevention. Their technical reliability, clean manufacturing profile, and compatibility with regulated environments make them indispensable in modern operational settings. For businesses seeking a dependable solution that aligns with best practices and industry standards, choosing the right swab can make all the difference.

English

English Français

Français Español

Español Português

Português عربى

عربى