Why SMS Fabric Is the Preferred Material for Surgical Gowns in Modern Operating Rooms

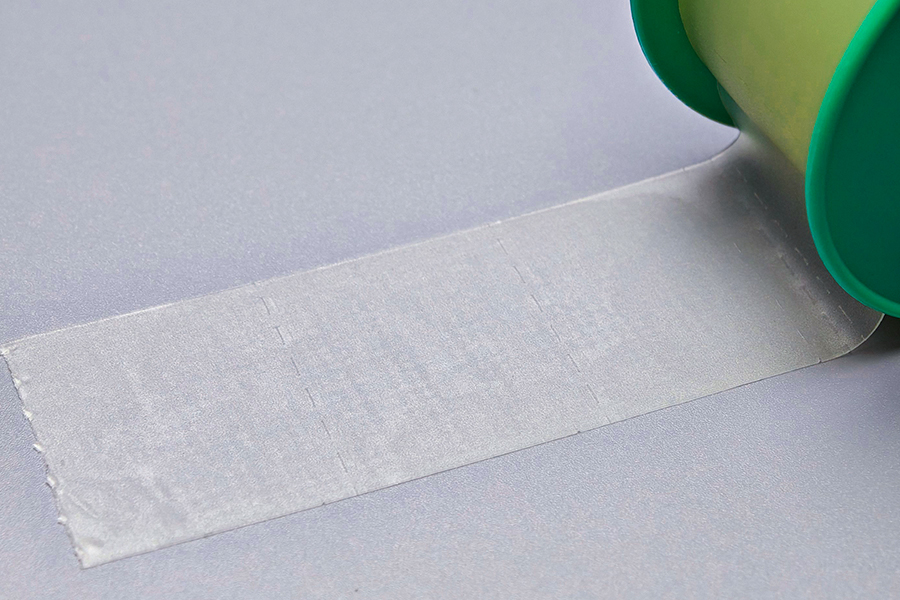

In the world of surgical gowns, material choice isn’t just a matter of comfort—it’s a critical decision that directly impacts protection, performance, and safety in clinical environments. One of the most widely adopted materials in recent years is SMS, a tri-layer nonwoven fabric made from Spunbond-Meltblown-Spunbond technology. This unique construction offers a balance of strength, filtration, and breathability that makes it particularly suited for demanding surgical procedures where both patient safety and healthcare worker protection are non-negotiable.

The outer spunbond layers of SMS fabric provide mechanical strength and durability, helping surgical gowns resist tearing and abrasions during prolonged procedures. These layers also contribute to the gown’s resistance to fluid splashes, an essential barrier in surgeries with high exposure risk. Nestled between them, the meltblown layer is the true filtration workhorse—it traps microscopic particles, offering a reliable defense against blood, bodily fluids, and potential microbial contaminants. This combination of toughness and filtration is precisely why SMS material has become the gold standard for surgical apparel.

From a wearability perspective, SMS-based surgical gowns strike a fine balance. Unlike older or single-layer alternatives that often compromise either protection or breathability, SMS allows air and moisture vapor to pass through while keeping harmful liquids out. This ensures that surgeons and operating room staff stay cooler and more comfortable during lengthy operations, without sacrificing the protective function that gowns are primarily intended to serve. A well-designed gown made of SMS can genuinely improve performance by minimizing heat stress and distraction.

One of the lesser-discussed advantages of SMS fabric is its compatibility with various reinforcement techniques. High-risk zones—typically around the chest, sleeves, and lap areas—can be further layered or sealed without affecting the gown’s overall flexibility. This allows manufacturers to tailor gowns for different surgical risk levels, from general procedures to high-exposure operations, all while using the same core material. It’s a testament to the versatility and customizability of SMS, which is why many hospitals prefer sourcing a consistent material base for their full range of surgical gown requirements.

In terms of quality assurance, SMS material responds well to sterilization processes, whether by ethylene oxide or gamma radiation, maintaining its barrier properties and structural integrity. That means surgical gowns can be reliably sterilized at the production level without degrading performance, meeting global standards such as AAMI Level 3 and 4 when designed accordingly. As a manufacturer committed to delivering consistent performance, we choose SMS not only for its proven effectiveness but also for how it aligns with the stringent compliance requirements of both domestic and international markets.

From a procurement standpoint, SMS-based gowns offer a practical advantage by reducing variability in supply chain sourcing. The material’s widespread use across the healthcare industry ensures steady availability and pricing, which helps avoid the disruptions that can occur with specialty or composite fabrics. For buyers and medical institutions seeking reliable, protective, and cost-effective surgical gown solutions, SMS-based options present a smart, scalable choice—particularly when ordered in bulk configurations with tailored sizing and reinforcement options.

As a supplier and exporter with deep roots in surgical textile manufacturing, we understand the importance of combining proven materials with thoughtful design. SMS fabric is not just a trend—it’s a well-established solution backed by performance data and real-world results. When selecting surgical gowns for your facility, understanding the science behind the fabric can help you make informed choices that protect your teams and support surgical excellence.

English

English Français

Français Español

Español Português

Português عربى

عربى